It's been a long while since I've been here & those who know of me know that some time late last year, my 25D blew up. (Rod #3 punched a hole through the block).

I recently obtained a 22E & decided to make another DOHC version since the block I got had wiring that was not compatible to my car. This is my second time making one of these & so far, it turned out good. I still have yet to start it due to waiting on tomorrow for my paycheck, then I'll be able to buy the fluids needed to start it up. For now, I'm gonna' feed your eyes with some pictures. (People, whenever you work on engines, keep your bolts/nuts/screws together in bags (label the bags) so that they don't get lost & keep in mind that it is imperative that they go back EXACTLY WHERE THEY CAME FROM.)

When I first got it, it looked like this...

After a few minutes of examining it closely, I began to take it apart.

This engine was said to be a 1995. This pic confirms it.

After more time, I removed the intake & all of the smaller things bolted or screwed to the engine & began to remove the cylinder heads. (Follow the service manual removal procedures for the intake & cylinder heads.)

These must be the old style head gaskets...

I like the way that my new ones look a lot better.

For those of you wondering if the 22E/25D intakes can be swapped, no, they cannot. They have completely different bolt patterns. If you use the 25D heads, you must use the 25D intake & wiring harness. (25D bolt pattern below).

The older style & newer style timing belt tensioners & their back plates are completely different. If you use the new style, you must use the plate that it bolts into. (Replace the tensioner if it is used).

There were changes to the EJ22E during it's run from the cylinder heads to the piston crowns. The top is the 1995 piston crown & the bottom is the 1998 piston crown.

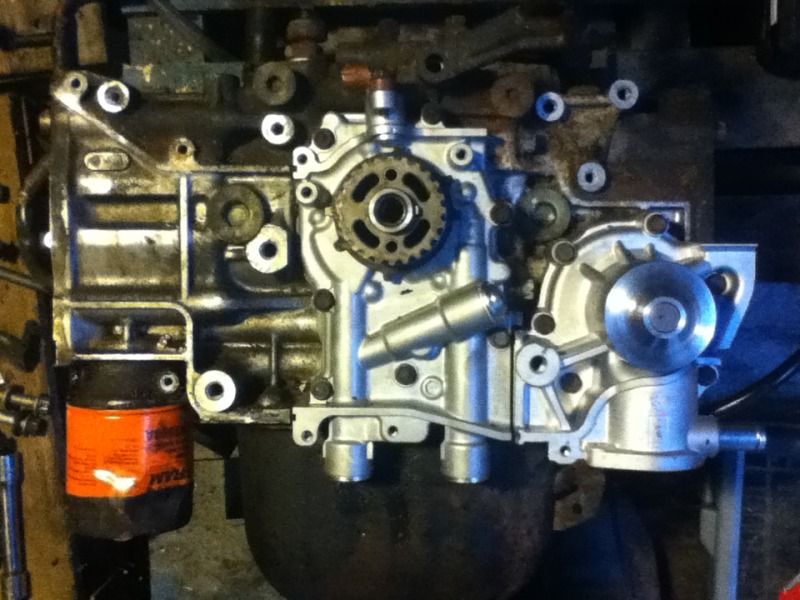

I believe that it doesn't hurt to have an 11mm oil pump for this kind of frankenstein since it will be run hard a few times once I break it in. Btw, the crank gear slides right out with no difficulty. If you do experience a little resistance, it's most likely corrosion & you'll have to put some penetration oil on it. Be patient if you have to do that. Btw, 22E & 25D crank & cam sensors are the same.

On our autos, there are 4 12mm bolts holding the flexplate on the torque converter. DO NOT REMOVE THE TORQUE CONVERTER. Turn the crank to access the 4 bolts & remove them (turn them counter clockwise).

Btw, DO NOT FORGET to replace the seals when you have everything apart. This goes for the rear main seal & resealing the oil separator behind the flywheel/flexplate. If you have an older EJ, it most likely has the plastic cover. Replace it with the upgraded metal cover.

I have an intake manifold spacer on my frankenstein. To install one in general, you have to cut the EGR valve pipe behind the left head & extend it a little more than the length of the spacer.

This next pic is a demonstration of how 22E MLS gaskets look on the 25D heads.

If you put together a DOHC EJ22E, assemble it as you would a 25D & use the 25D head bolts (22E bolts are too long), oil dipstick (25D dipstick has a higher mounting point), & black coolant pipe (22E pipe will NOT fit around the left DOHC head.)

Follow the factory service manual for the 25D to reassemble everything & make sure bolts & screws go back in their exact same spot. The end result will look just like a 25D.

If there are any questions, I'll answer them to the best I can. Btw, the final compression ratio I calculated with this particular engine was 8.8:1, which should be somewhat decent until I add a turbocharging kit. To anyone wondering if our pistons come up over the deck, yes, they do.

The world's #1 resource for everything Subaru, with a core focus on supporting every individual in a positive environment, regardless of experience & technical ability.

Please take a second to click here to register, and in a few simple steps you will be able to enjoy a "NO DRAMA" community. Once registered please introduce yourself.

Thank You.

Please take a second to click here to register, and in a few simple steps you will be able to enjoy a "NO DRAMA" community. Once registered please introduce yourself.

Thank You.

Thanks:

Thanks:  Likes:

Likes:

Register To Reply

Register To Reply

Bookmarks